By Mario Pierobon – © GE Digital

Given the take-off weight requirements that dictate flight data monitoring (FDM) in air operations regulations, FDM

is often not required in business aviation operations. Safety and operational benefits, however, can be expected for

business aircraft operators wanting to commit to an FDM system. In this first of a two-part story on FDM in business aviation, we shall explore the benefits of FDM and how to establish FDM objectives.

Safety and operational benefits

FDM is a safety tool that is used to improve performance. It allows operators to review routine flight data to identify potential hazards before they become incidents or accidents, observes Bryan Burns, president of the Air Charter Safety Foundation. “Hazards that can be identified with FDM data can include SOP drift, challenging airports, or high-risk events. Identifying these hazards allows the operator to implement corrective actions to improve performance”, he says. Luke Bowman, a product director for GE Digital’s Aviation Software business, believes that FDM along with SMS is a core part to having a safe operation. «We have shown through our work that once operators have an FDM program, critical safety events can be reduced by approximately 50% during the first five years they are enrolled when the appropriate safety culture and practices are applied. Given the cost of an aircraft, fuel, Internet connectivity, etc., FDM is a small price to pay for safer travel», he says. Burns points out that an FDM program can also show positive trends, not just improvements but also where the department excels. «Spreading awareness of the ‘good news’ improves confidence in the operation and is good for morale», he affirms. «With more advanced FDM systems, FDM can be used to monitor engine data to improve operations, reduce fuel consumption, and improve aircraft reliability».

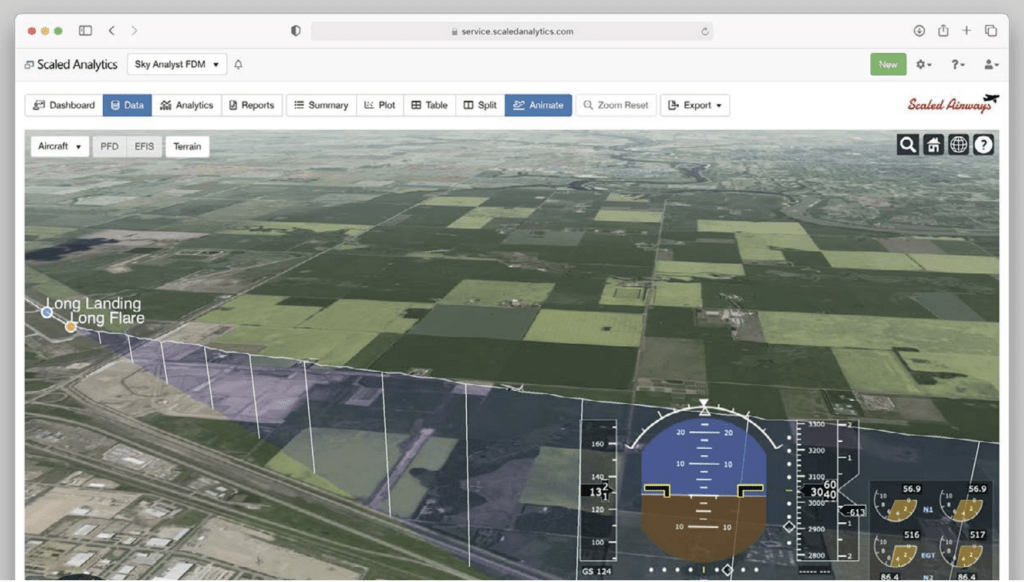

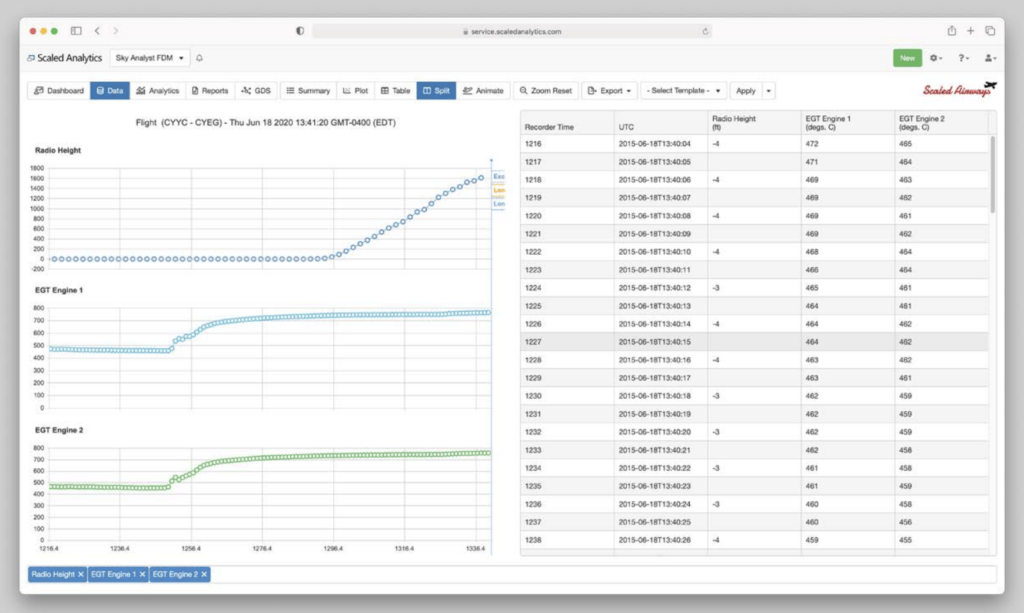

The majority of modern aircraft today have some sort of flight data collection system; even light aircraft can store a large amount of valuable, high-quality data, according to Dion Bozec, president and CEO of Viemo Scaled Analytics. «If one is not using that data in some capacity, one is effectively just ‘throwing it away’. Data can tell things about the operations that one may not know or confirm some elements that one ‘thinks’ one knows», he says. «For the most part flight data is very objective so it can be used to great effect to identify shortcomings in operations or identify trends that are developing over time». According to Everett Brady, FDM Manager at SKYTRAC, FDM is a valuable technology that improves overall safety of those onboard. «Insights generated by FDM can pinpoint common, repeated SOP issues such as hard landings, so operators can correct these actions through targeted training programs», he says. «In the short-term, identification of these trends can improve safety, and in the long-term, they can improve operational efficiencies and reduce costs to the operator».

Traditionally, flight operations wait for a check-ride to identify and correct any weaknesses but this kind of interventions are at the pilot/flight crew level, according to Bozec. «FDM programs can help to identify flight operation issues at a systemic level, discover weaknesses in the SOPs, and improve the approaches into certain airports», he says. «Once they are identified and corrective actions are put in place, the FDM program will help you assess how well those actions are working. There really is no operator that is ‘too small’ to benefit from FDM. I have personally seen an operator of a single aircraft update their training program based on the information learned through FDM in less than two months. The improvements were immediate and dramatic. Of course, not all operators will experience similar results but until one does not start regularly looking at the flight data, one does not know what one does not know»

Setting the objectives of FDM

According to Bowman, when it comes to setting the objectives of the FDM system the business aviation organizations should think about how they want FDM to fit into their overall safety ecosystem. «This is why we partner with leading SMS providers in order to connect FDM and SMS into a seamless process», he says. Burns believes that there are two main ways to identify FDM goals. “One is more formal than the other, but both have value. First, one should ask the responsible executive, chief pilot, or director of safety «what keeps you up at night?» Based on that answer, one can then start using FDM to measure those items and see if the intuition is correct or not”, he says. «Second, one would like to talk to other FDM users and ask them what they are seeing in their data. We tend to see the same types of problems in data; flaky approaches and flaky landings are typical occurrences. Focusing on improving performance in these areas will likely see improved performance in all phases of flight. The mindset needed to improve the approach and landing – namely tighter SOP compliance, good CRM, and increased awareness – will carry over to the entire flight».

The objectives of an FDM program depend largely on the organization’s maturity with FDM/FOQA and their technical capacity, according to Brady. «Organizations without dedicated flight data analysts may consider using a managed service to glean insights, while the organizations with dedicated FDM departments may leverage FDM software to generate their own insights aligned to their own objectives», he says. «It is important to involve all relevant stakeholders, such as pilots, maintenance personnel, and safety departments in the process as their input and buy-in will be critical for the success of any FDM program». For most operators, it is much easier to set goals once they start the program, affirms Bozec. «Only after looking at flight data, after a month or so, one has a baseline to start with. If things are going well, the goal may simply be to maintain the high level of performance already available. If there are areas that can be improved (which is much more common), one can set the goals accordingly», he says. «One thing to keep in mind at a company level is that flight data can be used for more than improving flight safety. For example, some of our customers also use their data for maintenance troubleshooting, engine condition monitoring, and fuel consumption tracking. These are certainly capabilities that one can put a dollar amount on in terms of savings. If cost is a barrier, it may be worth trying to set secondary goals within other departments of the organization, such as maintenance». Brady also thinks that the operators should focus on other areas of improvement in flight operations, maintenance, and training based on the analysis of historical flight data to determine the best path forward. «Operators can participate (for free) in data sharing programs such as the FAA’s Aviation Safety Information Analysis and Sharing (ASIAS) system which allows operators to share their de-identified data and gain insights into the trends other operators are seeing. Occasionally, directed studies are issued, covering important safety topics supported by aggregate operator data across thousands of flights», he concludes.