By Christophe Le Dentu

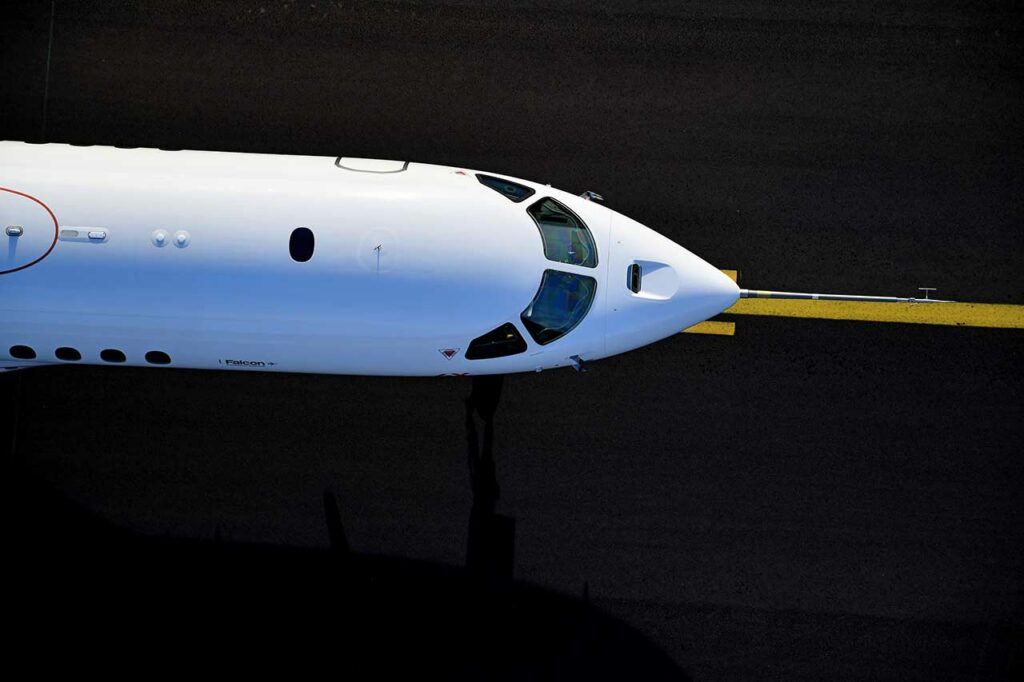

Launched four years ago in response to competition, the Falcon 6X program is being carried out with great vigor by the Saint Cloud-based manufacturer. And the schedule is all the busier since Dassault Aviation expects to have its twin-engine jet in service by the end of the year.

Since the inaugural flight of the first prototype last year, engineers have been busy. In addition to the complexity of any program, Dassault Aviation has also had to meet numerous challenges related to the Covid period, which has disrupted the daily routine of the teams in charge of developing the program. Despite this major setback, the aircraft manufacturer was able to reinvent its operating methods and keep to an already tight schedule to complete the various critical tests before the certification phase.

Genesis of the program

The least we can say is that the program of this twin-engine aircraft has been full of pitfalls. And not the least. The launch of the Falcon 6X in February 2018 is a quick response to the 5X program, which was abandoned two months earlier. This last one will leave for sure traces at the industrialist.

But the years of development of this one will not have in fact been lost. Far from it. The advent of the Falcon 6X, tends to show the incredible flexibility of the manufacturer and the fact that it remains well and truly present in the race of high-end aircraft of last generations and especially an active response has its main competitor Gulfstream which proposes the G500 and G600 on the market. From its predecessor, the Falcon 6X keeps only the vertical stabilizer, the cockpit and the width of the fuselage.

The latter, with a width of 2.18 m, is the largest in any category. Dassault has taken advantage of this program to offer a generously sized cabin with a length of 12.30 m and a height of 1.98 m. With this space, the Falcon 6X cabin can accommodate up to 16 passengers in its optimum configuration. While it undeniably offers unrivaled space for its segment, it also imposes the Falcon 6X on the market. Paradoxically, its interior dimensions and performance make the Falcon 6X an out-of-class aircraft.

While the cabin does rival an aircraft like the G650 in terms of space, the new Falcon’s range of 5,500 nm (10,186 km) compares favorably with that of its direct competitor on the market, the Gulfstream G500. The new jet from the St Cloud firm will be able to fly from Los Angeles to Geneva or Beijing to San Francisco in one go with 8 passengers on board according to FAA standards. This performance is due in part to the Pratt & Whitney Canada (P&WC) PW812D, a derivative of the P&WC PW800. A pragmatic choice that, as Eric Trappier, Chairman and CEO of Dassault Aviation, pointed out at the time, « was the closest solution with an aircraft that we have optimized and could benefit from this more powerful engine. »All in a very short time.

Innovations

With a cabin and performance that perfectly match market trends, which Dassault perfectly anticipated, the Falcon 6X is a concentrate of innovations and new technologies. This new program has enabled the redesign of key elements such as the wing. The wing has been completely redesigned to reduce the impact of turbulence to a minimum.

To do this, it is equipped with “flaperons”, a compressed term for flaps and ailerons, inherited from combat aircraft. This system is located in the center of the trailing edge of the wing and allows the aircraft to increase its drag, without losing lift or speed. The “flaperons” and all the moving surfaces of the wing will now be managed by digital flight controls. This is a first for Dassault’s civil aircraft range, enabling the Falcon to improve control of steep, low-speed approaches (109 kts – 202 km/h) over particularly short fields.

The Falcon 6X is already scheduled to operate to and from the iconic London City Airport in the heart of the UK’s capital. In addition to improved performance, the new wing is also equipped with a new fire protection safety system. The Falcon 6X is the first business jet to use a nitrogen-generating system to fill the space above the remaining fuel with an inert gas, providing greater protection against ignition. In addition to the aircraft’s structural aspect, innovation is also at the heart of the cockpit.

The aircraft manufacturer is continuing the development of the third generation of EASy digital avionics, which began with the 5X. The arrival of the Falcon 6X marks the de facto integration of systems previously provided as options on other models. In fact, the 6X is offered with the FalconEye system, developed in collaboration with Elbit, combining synthetic vision (SVS) with infrared vision (IR), as well as the FalconSphere II electronic flight bag (EFB).

To perfect its twin-engine aircraft, the aircraft manufacturer has also set a new standard in the field of maintenance with the FalconScan system, which provides real-time diagnostics of all parameters during flight. Connected to computers via an Ethernet network, it continuously measures more than 10,000 parameters on the aircraft, indicating the root cause of any problem. Dassault has left nothing to chance and has swept up a wide range of technological and aerodynamic innovations to design this new flagship.

Cabin renewal

The Falcon 6X is the first aircraft in the Falcon range to be designed around the cabin, as Eric Trappier emphasized at the launch: “The industry trend is towards more spacious, high-ceilinged interiors, and this is precisely what customers have been asking for in our new Falcons,” he added, “We have designed the Falcon 6X around the cabin, to put the passenger at the center, while offering the high performance and flying qualities that customers appreciate in Falcons. »

The studio, led by Agnès Gervais, head of interior design at Dassault Falcon, drew inspiration from designs originally created for the Falcon 900LX. In fact, the interior of the new jet features a design that emphasizes curves. According to the head of the studio, it is as close as possible to the aesthetic aspirations of the moment, with the integration of technology in the design to achieve maximum purity of lines.

In addition, the design studio emphasized the lighting effect, as Agnes Gervais points out: “We paid particular attention to light and color, especially at the entrance“. The judicious balance between contrast and luminosity was achieved by the Skylight, a zenithal electrochromatic window at the entrance to the aircraft, as well as by the 28 windows, 10% larger than those on the Falcon 8X, running along the fuselage. The strength of this design, reinvented for the occasion, lies in the large interior space of 52.2 m3, which can be divided into three living areas.

The rear design allows, among other things, the creation of a personal suite with the possibility of transforming the seat into a bed. The crew has not been forgotten, as Dassault offers an optional crew rest at the front of the aircraft for long-distance flights. In addition to space, Dassault is also banking on a very low noise level and an innovative air management system.

Initial flight tests have shown remarkable results in terms of noise levels, and engineers are confident of achieving noise levels as low as those recorded on the Falcon 8X, which is currently the quietest business jet of any category. Regarding cabin air filtration, Dassault says it has designed HEPA/ULPA filtration systems capable of exceeding the minimum air quality requirements by 10 times and collecting 99.97% of all airborne particles.

First production aircraft

Bolstered by its strengths and just over three years after its launch, the program teams successfully carried out the maiden flight of the S/N 01 prototype on March 10, 2021. With Bruno Ferry and Fabrice Valette at the controls, the first production 6X made a flight of nearly two and a half hours and performed in accordance with the test plan, which aimed to test the piloting qualities, the engine response and the behavior of other onboard systems. During this flight the aircraft reached an altitude of 40,000 ft (approx. 12,200 m) and a cruising speed of Mach 0.80.

In order to spread out all the tests, which are mainly carried out from the Dassault Aviation flight test center in Istres, the aircraft manufacturer has developed four prototypes. While the first two aircraft are mainly dedicated to systems and performance tests, the SN/03 aircraft is equipped with a full cabin and is used for acoustic and thermal tests, as well as to evaluate cabin pressurization and airflow for maximum passenger comfort.

The S/N 04 is the first production aircraft to be equipped with a full interior and used to demonstrate the operational maturity of the aircraft’s systems. According to the manufacturer, each test aircraft will perform two to three flights per week, depending on the period, for several hours per flight. In October, Dassault announced that test points beyond Mmo and Vmo were complete and that all aspects of flight testing, from systems development to aircraft performance and envelope expansion, were proceeding smoothly. In addition, the manufacturer also tested its aircraft in extreme cold conditions, which were divided into two sessions.

A first session last December in Iqaluit, a tundra town in the far north of Canada, when temperatures dropped to -25°C (-13°F). A second phase, also in Iqualit in February, saw the engineering team of technicians and pilots from Dassault Aviation and engine manufacturer Pratt & Whitney Canada endure freezing temperatures as low as -37°C (-35°F) for the long tests. According to Dassault, the jet was parked in the cold for three successive nights and was subjected to different start-up sequences each morning during the Arctic ground test campaign.

Teams then powered up the aircraft and performed engine ground tests and high-speed taxi tests. The ground tests were followed by a test flight during which anti-icing systems and handling qualities were checked, as well as fuel and hydraulic fluid temperature stability, while the aircraft remained in a holding pattern at 10,000 feet.

Certification on track

The cold weather campaign was a success, with a total of 50 hours of testing. While this is an essential step for the program, pure performance is not forgotten. In March, Dassault test pilots pushed the Falcon 6X beyond its maximum operating speed of Mach .90.

In a subsequent test, they pinned the speedometer at Mach .97 and the aircraft performed flawlessly, proving its structural robustness and superior maneuverability. These are qualities that Eric Trappier did not fail to underline when he declared during the announcement of the group’s results that « the aircraft’s flight behaviour is excellent and its performance is in line with our expectations, » adding that « once our intensive test and demonstration campaign is over, customers will be assured of taking delivery of a mature aircraft. » After an intensive flight test campaign, the program accumulated in April about 800 flight hours spread over more than 300 flights.

Based on encouraging results and an initial schedule that was perfectly met, Dassault Aviation unveiled the delivery of the fifth aircraft in February, the first production aircraft at the Little Rock site in Arkansas. This is an important milestone for the company, as the arrival of this first production aircraft will enable it to validate new engineering solutions aimed at accelerating the development and delivery cycle.

A dedicated 6X engineering team has performed robustness and cycle tests on equipment and components to prepare them for production. Upstream, engineers also designed processes that will allow for one-shot installation of the interiors, reducing the time required for integration work. Once fully equipped, the SN/04 and SN/05 aircraft should begin a world tour in the second half of the year, not only to validate various parameters, particularly in terms of performance on long-distance routes, but also to “demonstrate the aircraft’s operability, while presenting it to potential buyers throughout the stopovers,” says Eric Trappier.

While waiting for the summer, Dassault is preparing the first public presentation of the Falcon 6X on the EBACE show floor. This will be a major event at EBACE 2022, which should be of particular interest to the public.

Dassault’s new flagship is only a few months away from entering service. With its performance and unrivaled cabin space in this segment, it is an understatement to say that the Falcon 6X is eagerly awaited in the business aviation sector. While Dassault’s main historical market remains the United States, the aircraft manufacturer is also counting on the new jet to win new market share not only in Europe and the Middle East, but also and especially in Asia, where cabin space is particularly important. The Falcon 6X is already a trailblazer, and should give Dassault a head start in this fiercely competitive market.