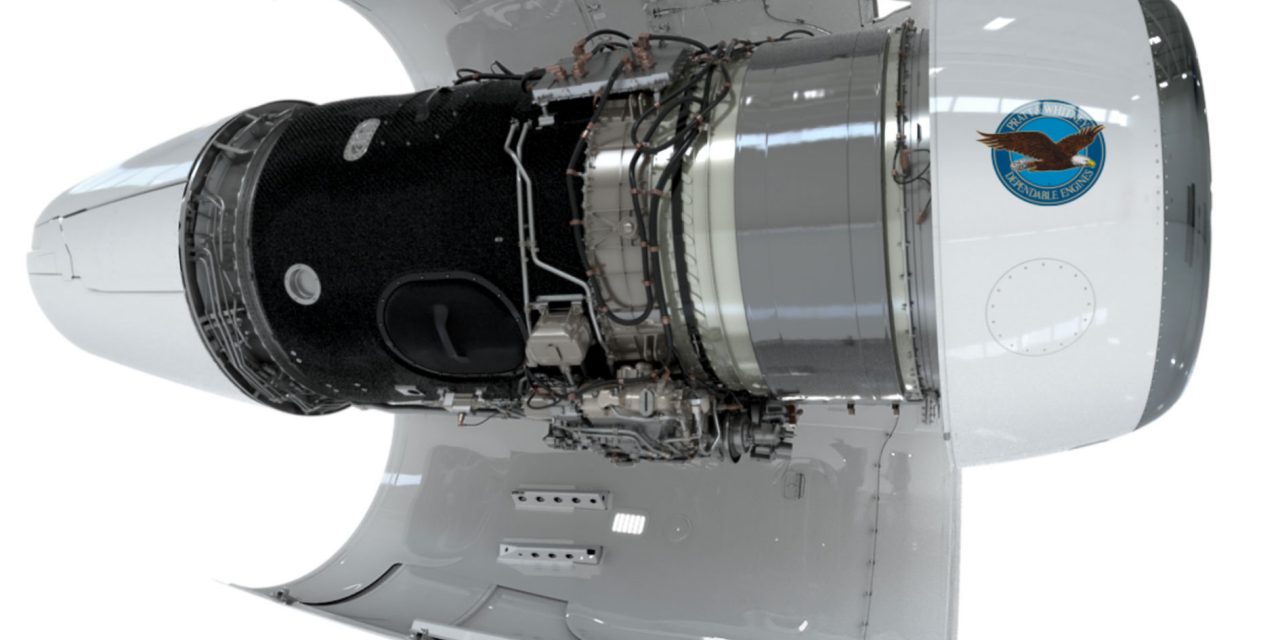

The ground-breaking PurePower PW800 turbofan engine is entering the key final steps as it proceeds towards entry into service announced P&WC. The PurePower PW800 recently reached the milestones of 16,600 hours and 16,800 cycles, including both ground testing and flight testing on P&WC’s flying test bed and Gulfstream G500 and G600 flight test aircraft.

Preparations for the engine’s entry into service are in full swing, with the addition of the European Aviation Safety Agency (EASA) and the Federal Aviation Administration (FAA) Type Certifications received on August 31, 2017 and in February 2017, respectively.

P&WC has taken significant steps to ensure that the company’s global support network is fully ready to provide operators with rapid, reliable and customized service. More than 150 frontline representatives have received training to provide customers with dedicated assistance going forward. More than 90% of the spare parts inventory has been stocked in parts distribution centres worldwide and are ready to be dispatched. Technical publications are 100% complete as a result of a strong ongoing collaboration with Gulfstream. The initial overhaul shop is ready to complete a final certification audit. These latest developments demonstrate that the PurePower PW800 is poised for a smooth takeoff.

“The PurePower PW800 is the only engine in the 10,000- to 20,000-lb thrust class that’s primed to enter service. It has proven its capacity to meet and exceed targets throughout many hours of comprehensive testing, making it the new benchmark in its class for performance, maintenance and reliability,” said Scott McElvaine, Vice President, Marketing and Customer Service, PurePower PW800 engines. “We look forward to further develop our relationship with Gulfstream and its operators and ensure our teams are ready to fully support the entry into service process.”

Thanks to its robust design, the engine is expected to deliver best-in-class availability to operators, with a predicted 99.99% dispatch reliability. It also offers greater ease of maintenance than any other engine in its class, with a projected 40% reduction in scheduled on-wing maintenance events plus a 20% reduction in inspections. It significantly raises the bar for time on wing, with the first shop visit targeted at 10,000 hours or more. It provides additional value for operators through double-digit improvements in fuel efficiency and noise emissions. Its low-noise design and low vibration levels result in an exceptionally quiet cabin, enabling a more comfortable passenger experience.

Seamless, proactive and predictive maintenance.

P&WC is rapidly advancing the digital interconnectivity of its frontline customer support and data-driven engine services and solutions for a seamless, proactive customer experience. P&WC’s Digital Engine Services Platform, which provides preventative, data-driven maintenance management and consulting services to customers, will be rolled out to PurePower PW800 customers. Supported by a dedicated group of aviation technicians and data analysts who leverage near-real-time full-flight data, the Digital Engine Services Team will conduct daily reviews of customer data so that maintenance requirements can be addressed proactively during scheduled field interventions. Similarly, P&WC’s premium-level ESP PurePower PW800 program – in which customers can enroll now – provides proactive solutions and service to maximize availability and value. “As the world prepares for the Gulfstream G500 entry into service powered by our PurePower PW800 engines, we have delivered an all-inclusive coverage plan focused on a preventive maintenance philosophy,” said McElvaine. “It is backed by a worldwide 24/7 action team including field support, engineering and operations specialists to support smooth and optimized flight operations.”